Hydraulic cylinders

Mobile | Industrial | Marine | Energy

Different types of hydraulic cylinders

We supply the hydraulic cylinder you need for your hydraulic application.

What is a hydraulic cylinder and why do you need it?

Hydraulic cylinders convert hydrostatic energy into mechanical energy. They are considered as motors or as actuators capable of producing work. Hydraulic cylinders differ from hydraulic motors, however, as cylinders carry out a linear (translatory) movement instead of a rotary movement. The force F in Newton of a hydraulic cylinder is directly related to the maximum operating pressure p in bar and the effective area of the piston A in square centimeters.

How much force can you actually get? Want to see the mathematics behind hydraulic cylinders: F = p · A [in kN]

The effective area of a cylinder is the difference between the area of the piston and the piston rod of the hydraulic cylinder. At constant pressure, a cylinder with a larger effective area will produce a larger force. As explained above hydraulic cylinders are also referred to as linear motors. For hydraulic motors a similar mathematical relation exists to calculate the torque of the motor based on the maximum operating pressure and displacement.

Hydraulic cylinders are used to perform work where loads must be lowered, locked, lifted or moved

In hydraulic cylinders, two functional types can be distinguished: double-acting and single-acting cylinders. Single-acting cylinders have one effective area, located on the bottom side, which can exert force in one direction only. The single or double-acting differential cylinder is generally used in mobile and industrial hydraulic systems. The most common design principles of the hydraulic differential cylinder are tie rod, mill type and roundline cylinder design.

Tie rod cylinders

Standards include DIN, ISO, ANSI and NFPA. Tie rod cylinders are used in machine tools and manufacturing devices because of the space-saving compact design.

Type of tie rod cylinders

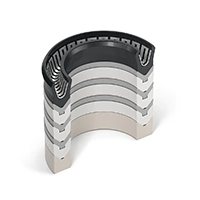

Roundline cylinders

Roundline are well known for their robustness and fatigue free operation at maximum pressure. It is actually a heavy duty mill type cylinder concept.

Type of roundline cylinders

Custom hydraulic cylinders

Custom hydraulic cylinders are designed and build to fit your requirements seamlessly. Choose from a custom hydraulic cylinder or servo cylinder systems.

Type of custom hydraulic cylinders

Cylinder spare parts

Hydraulic cylinder spare parts include piston seals and gland cartridge kit complete with seals. Accessories for cylinders are brackets and alignment couplers.